It was found that the optimum composition depends on various factors, including the feed size, the product size, the mill diameter and the breakage parameters. In all cases, binary mixtures of two ball sizes ( ...

The priority in sizing industrial ball mills by means of accurate measurements of the ..... Selection of rod mills, ball pebble mills and regrind mills. manufacturing processes US Envonmental Protect ball mill ( bl mil ) ( mechanical ...

how to design parameters for a ball mill – . design and analysis of ball mill inlet chute for,For designing and analyzing the Roller press circuit Ball mill chute, UMS diameter, RP+BM (Roller . Get Price Online

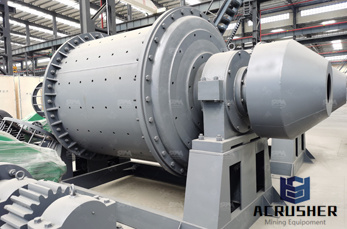

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Drum ball9 ...

Determination of breakage parameters in laboratory scale ball mill and scaleup of ball milling Birol Sönmez Research Assistant, Hacettepe University, Mining Engineering Department, Beytepe, ANKARA Halim Demirel ...

85 0 102030 % loading in the mill 3 4 5 6 7 Loading factor K 1 Grate discharge Dry Grate discharge Wet Overflow discharge Wet Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord ...

The grinding jar is arranged eccentrically on the sun wheel of the planetary ball mill. The direction of movement of the sun wheel is opposite to that of the grinding jars in the ratio 1:2. The grinding balls in the grinding jars are ...

There are many factors that affect the capacity of ball mill, and the following are the main factors.: 1. The speed of the ball mill at different speed of the cylinder, its movement law can be simplified to three basic forms. One is the ...

ball mill grinding: Topics by Sciencegov The specific energy was found to be dependent on operating parameters, Dependence of rates of breakage on fines content in wet ball mill grinding, variables like ball load, mill speed, particle ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant Sanjeev T. Patil Department of Metallurgical and Materials Engineering, Visvesvaraya National Institute of Technology, Nagpur440010, India. ...

2011/06/10· Trends with selection and sizing of large grinding mills — filed under: Print Edition by The Australian Journal of Mining ...

understanding ball mill sizing by l. g. austin – SAMAC understanding ball mill sizing by l. g. austin Description : Determination of breakage parameters in ... Determination of breakage parameters in laboratory scale ball ... ...

What is the best way to determine the balltopowder ratio for ballmilling a new material? Topics ... It strongly depends on the material and the mill parameters (energy, rpm, vial, filling vol., etc.) as Daniel mentioned as well as · ...

Grinding Down to the Nanoscale with Planetary Ball Mills Planetary Ball Mills. ... result is influenced by a number of parameters, especially by the rotational ... Ball Mill Design Power Draw EduMine Browser Tool for Ball Mill ...

Correlations for the Grindability of the Ball Mill As a. study of the Design Parameters For A Ball Mill effect of the various parameters on the performance of a ball mill. The basis of dimensional analysis approach as well as fractional ...

Browser Tool for Ball Mill Design Power Draw Control Ball Mill Design Power Draw Tool Parameters Values displayed with a may be changed ... click on a value to display an entry form ... or use the arrows right of a value to ...

Kruttschnitt Parameters, then Applying Effi ciency Factors D Burgess1 ABSTRACT Since the days of mandatory high cost pilot plant testing in 6 ft × 2 ft SAG mills autogenous griding/semiautogenous grinding (AG/SAG), mill ...

The model for optimal charge in the ball mill J. Min. Met. 43 A (2007) 21 For the requirements of the first part of investigations samples of quartz sand have been used of high purity(> 99 % SiO2), separated into four narrow size ...

Parameters Of Ball Mill Effect of ball mill grinding parameters of hydrated lime fine grinding Effect of ball milling parameters on the particle size in . – Springer. Get Price Online parameters for ball mill Modeling of operating ...

leading supplier of grinding mills under the Traylor brand name since 1902 and many of the largest plants operating today have these world renowned SAG and Ball Mills ...

Mill sizing method The Cement Grinding Office The mill sizing page: Please find below two calculators for sizing mills using the Bond and Rowland methods. Ball mill sizing: Calculator for ball mill(s) in a single... Read more

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH ...

Notes on Ball Mill Design Power Draw Power Draw is steady running power requirement ... ignoring drivetrain losses and startup loads. Power Draw is reduced for regrinding ... ie. if (Feed Size/Product Size) 105 Feed Size 10000 microns

Ball mill steel ball size ratio according to add the ball . Ball mill steel ball size ratio according to add the ball? Here we must consider four factors : the ball mill diameter size, hardness, ball mill ore ore particle size .

WhatsApp)

WhatsApp)