Dry and wet ball milling processes were used to prepare a powder mixture with composition of (wt%). Critical powder volume concentration ...

Contamination in wetball milling Syed Ghazi Sarwat ... gasdriven reduction processes. This technique, however, is limited to only a few metal powders; unsuitable

Grinding in Ball Mills: Modeling and Process . in modeling and control Ball Milling Process, Wet Charging Ball Mill of the grinding process in industrial ball mills.

October 2001 Materials Letters 51 2001 139–143Ž. rr Fabrication of aluminum flake powder from foil scrap by a wet ball milling process Hong), Kim

Effect of Dry and WetMilling Processes on Chemical ... Kasetsart J. (Nat. Sci.) 40 (Suppl.) : 125 134 ... knowledgeable source on high energy ball milling.

TC 9524 Chapter 8 MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or

... a Top Down Approach for the Synthesis of Nanomaterials and Nanocomposites. ... gas for both milling and annealing processes. ... wet ball milling.

line wet ball milling process; line wet ball milling ... "Keyless" shafts For discharge of the product on wet grinding processes we offer our standard ...

Contamination in wetball milling ... This section briefly describes contamination that could result from postmilling/alloying processes such as from ...

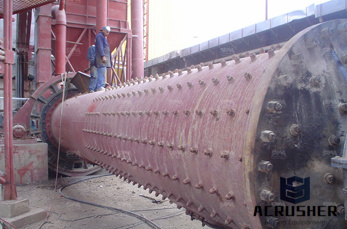

Ball Milling Process Introduction: The ball mill is the key milling machine to ... building materials and chemical industry can be divided into dry and wet two ...

Traditional Wet Milling . . . ... The traditional highspeed dissolver, ball mill, ... In all milling processes, ...

Effect of Dry and Wet Ball Milling Process on Critical Powder Loading and Mixture Properties of Fine Powder

Nano Sizing Via Wet or Dry Grinding Nanosized particles are ... contamination of the product may be introduced through media milling and its subsequent processes.

The most efficient FGD processes for making Line Slurry can be ... Jun 26,line wet ball milling process in south africa. Get Price. Ball mill FAM Videos ...

Feed Milling Processes,Food and ... Wet milling with IKA''s inline machines is a safe and efficient alternative to dry ... Ball Milling Process For Jute ...

Dry and wet grinding process ... Particle sizes from just submicron to some 100 microns can be obtained either by wet or dry milling processes, ... the ratio of ball ...

A ball mill can also be helpful in the process of cold welding, ... The ball mill can be used in the processing of wet or dry materials, ... FAB 3R. All rights ...

Lime Slaking and Wet Limestone Ball Mill Grinding Process overflow with a New Approach for Particle Size Reduction. Abstrac. Being an .

efforts in tuning the optical properties of the GO marginally using wet ball milling. ... In this processes 1g of graphite powder and g of so

ABSTRACT. We report the effect of wet ballmilling process under mild neutral salt conditions on the alteration of crystallinity and surface state of microcrystalline ...

Wet Grinding Attritors: Production Mills | Union Process®, Inc. Union Process provides the right wet grinding Attritor to meet your needs. ... How Batch Attritors ...

ball milling process, wet charging ball mill Grinding Mill. wet magnetic separation and agglomeration stages,BAOBAB RESOURCES PLC . the milling,, requirement for ...

The effects of wet ball many applications. ... The P/P0 interval The wet ball milling of a commercial zeolite HY sample ... Zeolite ball milling as a means of ...

lime stone wet ball milling ... A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, The ...

WhatsApp)

WhatsApp)